PTFE Glass for Life-Saving Neurovascular Interventions

Neurovascular diseases, such as aneurysms and acute ischemic strokes, present some of the most critical challenges in modern medicine. Much like the cardiovascular field, the neurovascular sector has seen a massive shift toward minimally invasive procedures. These interventions allow surgeons to navigate the intricate, tortuous pathways of the brain’s vascular system to treat conditions without the risks associated with open surgery.

The success of these delicate procedures relies heavily on the quality of the devices used, such as micro-catheters and guidewires. This is where advanced manufacturing materials like PTFE (polytetrafluoroethylene) glass play a pivotal role. Originally adopted for its unique chemical properties, PTFE has become a material of choice for next-generation medical manufacturing.

Today, PTFE glass is increasingly vital in the manufacturing of neurovascular devices. Its ability to support the creation of ultra-precise, smooth, and sterile lumens makes it an ideal component for the next generation of life-saving neurovascular technology.

Why PTFE Glass?

When compared to standard PTFE-coated stainless steel, PTFE glass mandrels offer compelling advantages, particularly for the high-stakes environment of neurovascular device manufacturing:

- Zero Contamination Risk: In neurovascular applications, particulate generation is a critical failure mode. Stainless-steel mandrels coated with PTFE can shed particles or leave residues, jeopardizing sterility. PTFE glass mandrels offer a clean, non-peeling alternative, greatly reducing the chance of contamination during the manufacturing process.

- Faster Production, Lower Cost: Stainless-steel mandrels often require long lead times and complex processing due to their raw materials. PTFE glass is not only more cost-efficient but can also be manufactured and delivered faster, helping manufacturers meet the urgent demand for stroke and aneurysm treatment devices.

- High Lubricity and Easy Extraction: Neurovascular catheters are often incredibly small and complex. PTFE glass delivers excellent lubricity, allowing for easy mandrel removal even from these tight-tolerance devices. In many cases, the mandrel can be extracted within seconds without the need for post-processing or risking damage to the delicate inner lumens.

- High-Temperature Resilience: Capable of withstanding heat up to 260°C (500°F), PTFE glass performs reliably during high-temperature reflow processes, making it suitable for a wide range of catheter-forming applications.

PTFE Glass from MCS

Medical Component Specialists has honed its grinding expertise for over 60 years, offering PTFE glass mandrels trusted by medical OEMs worldwide. These mandrels are frequently used in the production of catheters and other neurovascular components where dimensional precision is non-negotiable.

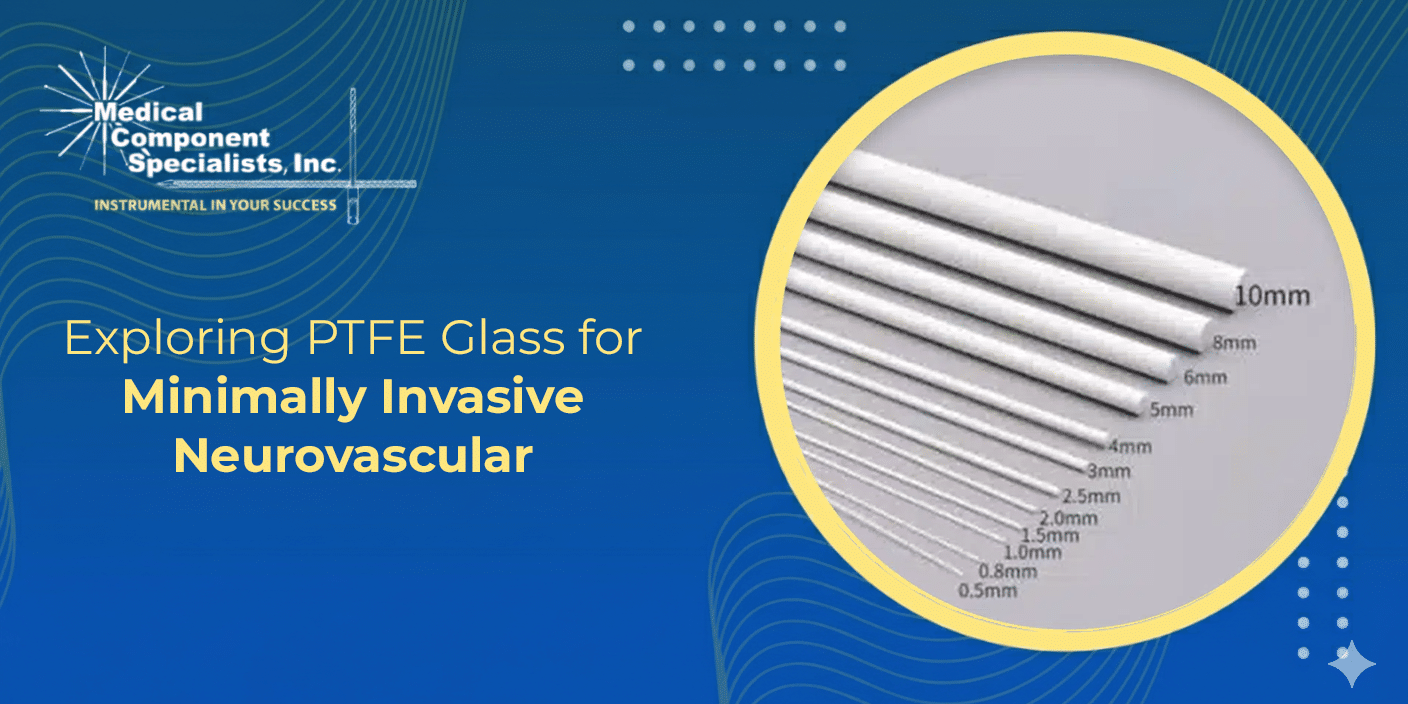

Whether you are replacing traditional stainless steel options or developing a custom device to navigate complex anatomies, MCS delivers unmatched precision, speed, and reliability. Our team can add steps, tapers, or other custom features with turnaround times typically under two weeks. For even faster delivery, our Quick Ship Program includes off-the-shelf solutions ready to ship the next business day.

With ISO 13485 certification, full in-line production capabilities, and high-volume CNC machining, MCS supports rapid prototyping and full-scale manufacturing. Our PTFE glass mandrels combine technical superiority with manufacturing agility, making them an essential component for modern neurovascular innovation.

Contact MCS to explore how PTFE glass can support your next minimally invasive neurovascular project.