As medicine continues to advance, neurovascular interventions are advancing with it. Conditions like arteriovenous malformations, strokes, aneurysms, carotid artery disease, and intracranial atherosclerotic disease, once requiring invasive procedures, can often now be treated with minimally invasive interventional techniques. For this reason, PTFE glass has become a topic of increasing interest within this market.

PTFE glass is the latest and greatest way to create smooth and consistent catheters, offering a compelling alternative to traditional methods. Unlike coatings that rely on bonding agents or PFAS‑containing adhesives, the unique composition of PTFE provides intrinsic lubrication for mandrels, allowing for a clean “quick release” during catheter production and assembly. The result is a cleaner, potentially safer product without the risk of PFAS contamination in the final device.

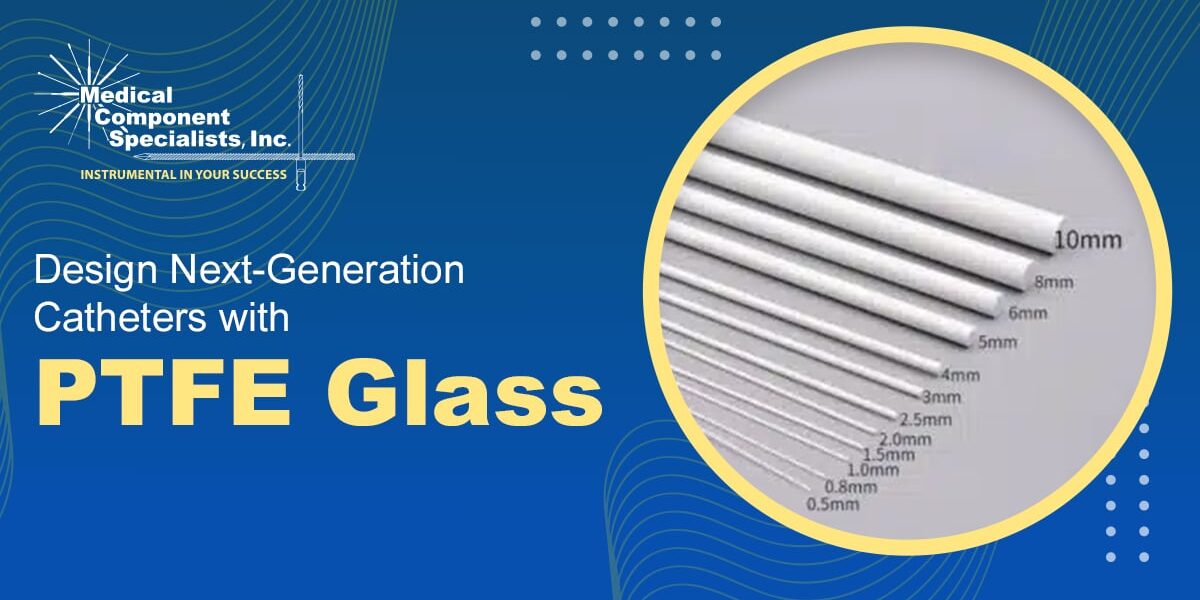

Beyond contamination prevention, PTFE glass delivers exceptional consistency and cost savings. Traditional methods typically carry lengthy lead times and higher costs due to complex raw materials and manufacturing processes. In contrast, PTFE glass is significantly cheaper to produce, more readily available, and uniformly consistent from batch to batch. Modern precision grinding technology further enhances their performance, yielding a high‑performance ground surface finish that rivals and often surpasses that of coated steel options.

For interventional neurovascular applications, ultra-precision tolerances as tight as ±0.0001″ mean these mandrels can directly replace stainless steel counterparts in virtually any setting. Their high lubricity, even before final grinding, ensures effortless removal and minimizes production issues. And with a thermal tolerance up to 260 °C (500 °F), PTFE glass is ideally suited for high-temperature catheter forming processes.

In minimally invasive interventional markets, where precision, safety, and efficiency are paramount, PTFE glass is not just preferred but essential to the next generation of catheter manufacturing.